PROJECTS

PROJECTS

- Top

- Projects

Our Journey of Boldly

Taking on Challenges to Meet the

Evolving Needs of the Times

To continue delivering unwavering value amidst ever-changing times, we have created new products for over 100 years, leveraging our cultivated technologies and their development. While the presence of carbon paper, our flagship product at the time of our founding, has diminished in the modern era, our newly developed products have seamlessly integrated into numerous industries and daily lives of end users, supporting everyday moments. Here, we introduce the projects we have undertaken, focusing primarily on our modern core product, Thermal Inkjet ink.

TIJ ink TIJ ink

-

Evolution of TIJ and GENERAL

Our Entry in the TIJ Business

in the Marking & Coding Sector and

Contribution to Expansion - As an inkjet ink partner of HP Inc., which handles head-integrated cartridges for TIJ systems, we have contributed to the advancement and market expansion of TIJ technology.

TIJ technology is a printing method that utilizes heat and surface tension to expel ink from a head-integrated cartridge using the pressure of vapor bubbles. While this technology is now established as well-known technology, solvent-based ink was scarce until the early 2010s, causing it to lag behind the dominant Continuous Inkjet (CIJ) and Piezo Inkjet systems. However, CIJ had limitations in high-resolution printing and required significant maintenance, prompting an increase in demand for alternative solutions in sites that require a printing process.

In response, we focused on developing solvent-based inks optimized for TIJ systems alongside our existing water-based inks. This journey was not easy, but the experience of creating something new and the excitement of surprising the market with innovative ink led to our business expansion and powers our growth. The fusion of our solvent-based ink and TIJ technology, which offers flexibility for diverse applications and small-lot, multi-variety production with minimal effort, provided a new choice in the marking and coding market.

Today, we are recognized as a leading company in the TIJ ink market, with General becoming synonymous with solvent-based ink. Moving forward, without settling for past achievements, we will continue expanding TIJ technology and solving industry challenges with our innovative inks including solvent-based ink.

TIJ ink / Use case in the construction industry Achieving Label-Free Printing with Revolutionary Solvent-Based White Ink

TIJ ink / Use case in the construction industry Achieving Label-Free Printing with Revolutionary Solvent-Based White Ink

This case highlights our proposal to construction material manufacturer Company A, which sought to improve production efficiency. We introduced a solution that combined solid white printing with solvent-based white ink and black ink printing, creating the appearance of a label without using an actual sticker. This approach unlocked new applications for TIJ and solvent-based white ink.

Background

Background

Improving Product Management by Eliminating Label Peeling and Staining Issues

Company A traditionally managed various industrial construction materials by attaching printed label stickers. However, standard labels had drawbacks such as smudging or peeling depending on environmental conditions, disrupting product and inventory management. Additionally, the labor involved in label creation and application, along with environmental concerns related to label waste, were issues that needed resolution. Given these circumstances, the company sought a direct printing solution to transition to label-free printing.

Improving Product Management by Eliminating Label Peeling and Staining Issues

Company A traditionally managed various industrial construction materials by attaching printed label stickers. However, standard labels had drawbacks such as smudging or peeling depending on environmental conditions, disrupting product and inventory management. Additionally, the labor involved in label creation and application, along with environmental concerns related to label waste, were issues that needed resolution. Given these circumstances, the company sought a direct printing solution to transition to label-free printing.

Solution

Expanding TIJ’s Potential with the Bold Idea of White Ink x Solid Printing SOLUTION

TIJ ink is typically used for printing variable information directly on substrates. Therefore, initially, direct printing with black ink seemed the most suitable approach. However, since the substrates were dark, black ink lacked visibility. White ink alone did not provide the necessary clarity either. Our solution was a two-step printing process: first, applying a solid layer of solvent-based white ink, then printing information over it with black ink. This innovative approach addressed multiple challenges at once and significantly improved production efficiency. While the concept itself might seem simple, this approach was only realized by General that offers TIJ-compatible solvent-based white ink. In that sense, this case showcases General’s pioneering spirit.

TIJ ink / Use case in the pharmaceutical industry Developing a Solvent-Based Fast-Drying Ink to Enhance Manufacturing Line Efficiency

TIJ ink / Use case in the pharmaceutical industry Developing a Solvent-Based Fast-Drying Ink to Enhance Manufacturing Line Efficiency

This case details our development of a solvent-based fast-drying ink for pharmaceutical company B, which needed a printing solution for blister packs for medicine. Previously relying on CIJ technology, the company sought improvements in equipment maintenance, ink safety, and odor control. Our solution introduced TIJ technology that can solve various issues while maintaining or enhancing the print quality of CIJ technology.

Background

Background

A Pharmaceutical Company’s Search for a New Ink to Improve Safety and Efficiency

The CIJ system required frequent maintenance and emitted strong solvent odors. Additionally, its dot-matrix printing method, which is a characteristic of CIJ systems, made achieving high-definition prints difficult, particularly on textured or glossy blister packs, reducing readability. For both pharmaceutical handlers and consumers, clear and accurate medication information is critical. Therefore, company B was seeking a replacement with a printing solution that eliminates these issues in a hurry.

A Pharmaceutical Company’s Search for a New Ink to Improve Safety and Efficiency

The CIJ system required frequent maintenance and emitted strong solvent odors. Additionally, its dot-matrix printing method, which is a characteristic of CIJ systems, made achieving high-definition prints difficult, particularly on textured or glossy blister packs, reducing readability. For both pharmaceutical handlers and consumers, clear and accurate medication information is critical. Therefore, company B was seeking a replacement with a printing solution that eliminates these issues in a hurry.

Solution

Combining HP Inc.'s Cartridges with Our New Ink for Fast-Drying, High-Resolution Printing SOLUTION

It seems that Company B’s concerns, other than those related to ink, were able to be resolved by adopting HP Inc.'s TIJ system, known for low maintenance. For ink as well, the problem of strong odor was resolved immediately. However, developing an ink that matched the fast drying speed of CIJ’s solvent-based ink was a major challenge. Through extensive discussions, manufacturing site visits, and prototype testing, we steadily refined the ink’s performance. Ultimately, we succeeded in creating an ink that allowed the company to confidently switch to TIJ technology. The newly developed ink, offering both fast drying and high-resolution printing, not only alleviated concerns but also highlighted General’s R&D capabilities in the industry.

TIJ ink / Use case in the automotive industry Transitioning from Thermal Transfer Ribbon to Inkjet Printing: UV LED-Curable ink for Rubber Belt Marking

TIJ ink / Use case in the automotive industry Transitioning from Thermal Transfer Ribbon to Inkjet Printing: UV LED-Curable ink for Rubber Belt Marking

This case explores our collaboration with automotive parts manufacturer C, which faced the discontinuation of its thermal transfer ribbon. We proposed thermal inkjet technology using ink cartridges together with UV LED-curable white and yellow ink for inkjet, achieving cost efficiency and process optimization while maintaining print quality.

Background

Background

Revising Printing Methods Due to the Discontinuation of Thermal Transfer Ribbons

For years, Company C used our specialized white and yellow thermal transfer ribbons to print part names and numbers on rubber sleeves which are materials used in manufacturing rubber belts. However, due to the discontinuation of raw materials for these ribbons, we had to cease supply after securing a two-year stock. A year later, the company requested us to find a way to reproduce the ribbon, which, while impossible, drove us to explore alternative solutions.

Revising Printing Methods Due to the Discontinuation of Thermal Transfer Ribbons

For years, Company C used our specialized white and yellow thermal transfer ribbons to print part names and numbers on rubber sleeves which are materials used in manufacturing rubber belts. However, due to the discontinuation of raw materials for these ribbons, we had to cease supply after securing a two-year stock. A year later, the company requested us to find a way to reproduce the ribbon, which, while impossible, drove us to explore alternative solutions.

Solution

Establishing a New Printing Method with UV LED-Curable ink SOLUTION

Thermal inkjet technology was the immediate alternative, but its suitability for this application required further evaluation. After analyzing the printing conditions and requirements, we proposed our newly developed UV LED-curable white ink, IQ131, which was developed at the same time as our thermal inkjet technology. Through multiple real-world tests owing to cooperation from Company C, we confirmed its strong abrasion resistance on rubber sleeves. Additionally, we selected IQ134CY, which was also just developed, as the yellow ink. By implementing these inks, we not only matched the quality of the previous ribbon method but also improved cost efficiency and process effectiveness, achieving an optimal marking solution for the company.

Screw-type RF tag Screw-type RF tag

Screw-type RF tag / Use case in the lifestyle goods industry

Achieving Success Through Over a Year of Prototyping and Evaluation

A Screw-Type RF Tag That Revolutionized Integrated Management in Manufacturing

Screw-type RF tag /

Use case in the lifestyle goods industry

Achieving Success Through Over a Year of Prototyping and Evaluation

A Screw-Type RF Tag That Revolutionized Integrated Management in Manufacturing

This case study presents a customized solution utilizing UHF-band RFID technology to improve traceability efficiency in the manufacturing sites of Company D, a household goods manufacturer. In this project, RF tags were required not only in multiple color variations but also with the capability to withstand high temperatures and liquid environments for accurate process tracking and data recording in the entire manufacturing process. By customizing a screw-type RF tag, we successfully met these requirements and contributed to solving the company’s challenges.

Background

Background

Challenges in Process Management

“We couldn’t find an RF tag suitable for our site.”

To monitor the progress of manufacturing processes, Company D had implemented a system that mainly relied on barcodes for tracking production components. However, due to repeated high-temperature treatments and liquid-based cleaning processes in the production line, labels displaying barcode information often peeled off, leading to fundamental management issues. Although the company had previously considered implementing an integrated management system using RFID, they had been unable to find an RF tag that could withstand such a unique environment while fitting into the operational workflow. As a result, they were forced to continue using a management method that lacked convenience. Under these circumstances, on-site demand grew for RF tags tailored to the production environment and unique operation to enable seamless RFID-based integrated management.

Challenges in Process Management

“We couldn’t find an RF tag suitable for our site.”

To monitor the progress of manufacturing processes, Company D had implemented a system that mainly relied on barcodes for tracking production components. However, due to repeated high-temperature treatments and liquid-based cleaning processes in the production line, labels displaying barcode information often peeled off, leading to fundamental management issues. Although the company had previously considered implementing an integrated management system using RFID, they had been unable to find an RF tag that could withstand such a unique environment while fitting into the operational workflow. As a result, they were forced to continue using a management method that lacked convenience. Under these circumstances, on-site demand grew for RF tags tailored to the production environment and unique operation to enable seamless RFID-based integrated management.

Solution

Customizing Screw-Type RF Tags to Withstand Harsh Environments SOLUTION

To address the challenges in achieving integrated management, we initiated the development of a specialized screw-type RF tag optimized for Company D’s production processes. The core objective of this project was to create an RF tag that could be used under extreme conditions, including solvent-based cleaning and heat treatment exceeding 100°C. By switching from traditional iron screws to stainless steel screws and customizing the materials and shape of the RF tags, we significantly enhanced the required operational performance. Furthermore, we conducted multiple on-site evaluations, testing various RFID readers, antennas, signal strengths, and installation conditions to improve reading accuracy. Consequently, by designing an optimal system for each stage of the complex manufacturing process, we successfully developed an RF tag that balances quality and functionality, making it viable for practical use after more than a year of rigorous testing and refinement.

Coating Coating

Coating / Use case in the electronic parts industry Enhancing the Quality of Electronic Components with Coating Technology in a Clean Environment

Coating / Use case in the electronic parts industry Enhancing the Quality of Electronic Components with Coating Technology in a Clean Environment

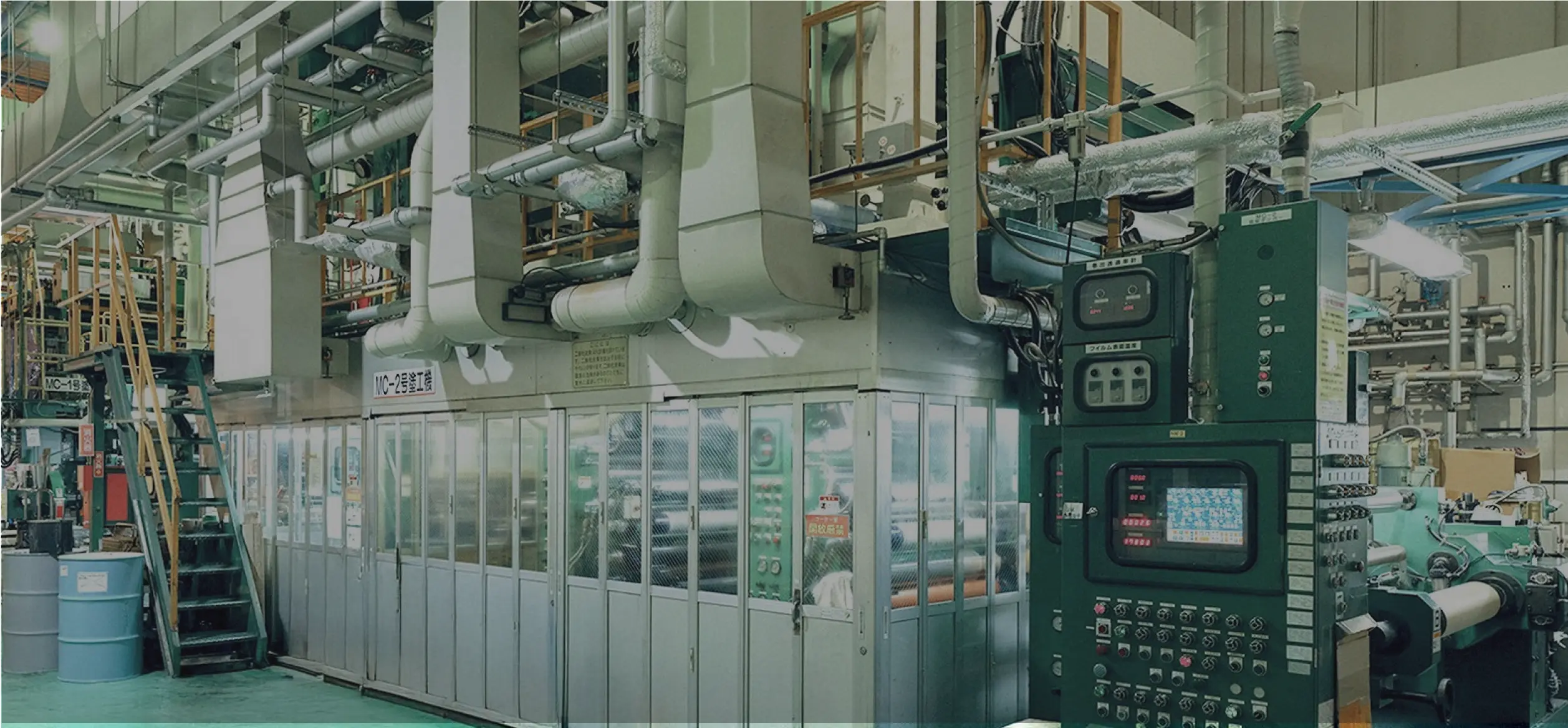

This case study details our provision of coating processing in a clean environment, a technology essential for strict quality control, to a leading electronic component manufacturer E. By applying coatings in an environment free from dust and impurities, we contributed to maintaining the high-quality finish of electronic components. This project also served as a catalyst for significant capital investment in advanced cleanroom-compatible equipment.

Background

Background

Challenges in High-Precision Coating for Electronic Components Requiring Specialized Environments

Company E sought precise and durable coating for their products but lacked an in-house processing environment compatible with cleanrooms. As a result, they had to outsource the work to external companies specializing in advanced coating technologies. However, traditional outsourcing involved separate companies handling the coating and firing processes, leading to variations in quality and increased management costs. Therefore, there was a pressing need for a solution that could integrate these processes under a single system.

Challenges in High-Precision Coating for Electronic Components Requiring Specialized Environments

Company E sought precise and durable coating for their products but lacked an in-house processing environment compatible with cleanrooms. As a result, they had to outsource the work to external companies specializing in advanced coating technologies. However, traditional outsourcing involved separate companies handling the coating and firing processes, leading to variations in quality and increased management costs. Therefore, there was a pressing need for a solution that could integrate these processes under a single system.

Solution

Achieving Integrated Processing in a Clean Environment Through Equipment Investment and Technological Innovation SOLUTION

To enable seamless coating and firing processes in a clean environment, we introduced cleanroom-compatible coating equipment and firing equipment. We established an integrated processing system with the aim of providing prompt responses and ensuring stringent quality control. Additionally, we made adjustments to the composition of the ink supplied by Company E and conducted repeated testing to determine optimal application conditions. We also fine-tuned the drying process to ensure uniformity of the applied ink and implemented inspection devices to monitor quality in real time. These advancements allowed us to achieve a high-precision coating technology for electronic components, fulfilling the quality requirements set by the company.

Unlocking the Potential of GENERAL Shape the Future with Technological Innovation and Value Creation to Contribute to the Growth of Society and Industry

In an era where digitalization is progressing and traceability is gaining importance, the demand for automatic recognition technology that enables contactless reading and writing, along with printing solutions that support such technologies, is expected to expand rapidly. Across various industries, there is a growing need for enhanced supply chain and logistics efficiency, as well as strengthened infrastructure management and security. Consequently, our business initiatives are also expected to continue evolving to address these challenges.

Despite being satisfied with a history spanning over 100 years, we remain committed to anticipating market needs and driving technological innovation through our ink development capabilities and coating technology. Furthermore, with our unwavering creativity that has enabled us to create added value since our founding, we will continue to support the growth and success of our customers' businesses.

Contact

CONTACT

For inquiries regarding contract manufacturing or products,

please feel free to contact us here.