For over a century, General has remained dedicated to craftsmanship, continuously shaping the course of time.

Looking back, our journey has been a series of challenges—each one an opportunity to create new value.

Since our founding, the fearless spirit of taking on challenges has been passed down without fading.

Even today, it remains the driving force that propels us forward.

We aspire to be a catalyst for change—driving transformation while remaining true to ourselves.

With this conviction in our hearts, we take yet another bold step forward today.

BUSINESS

BUSINESS

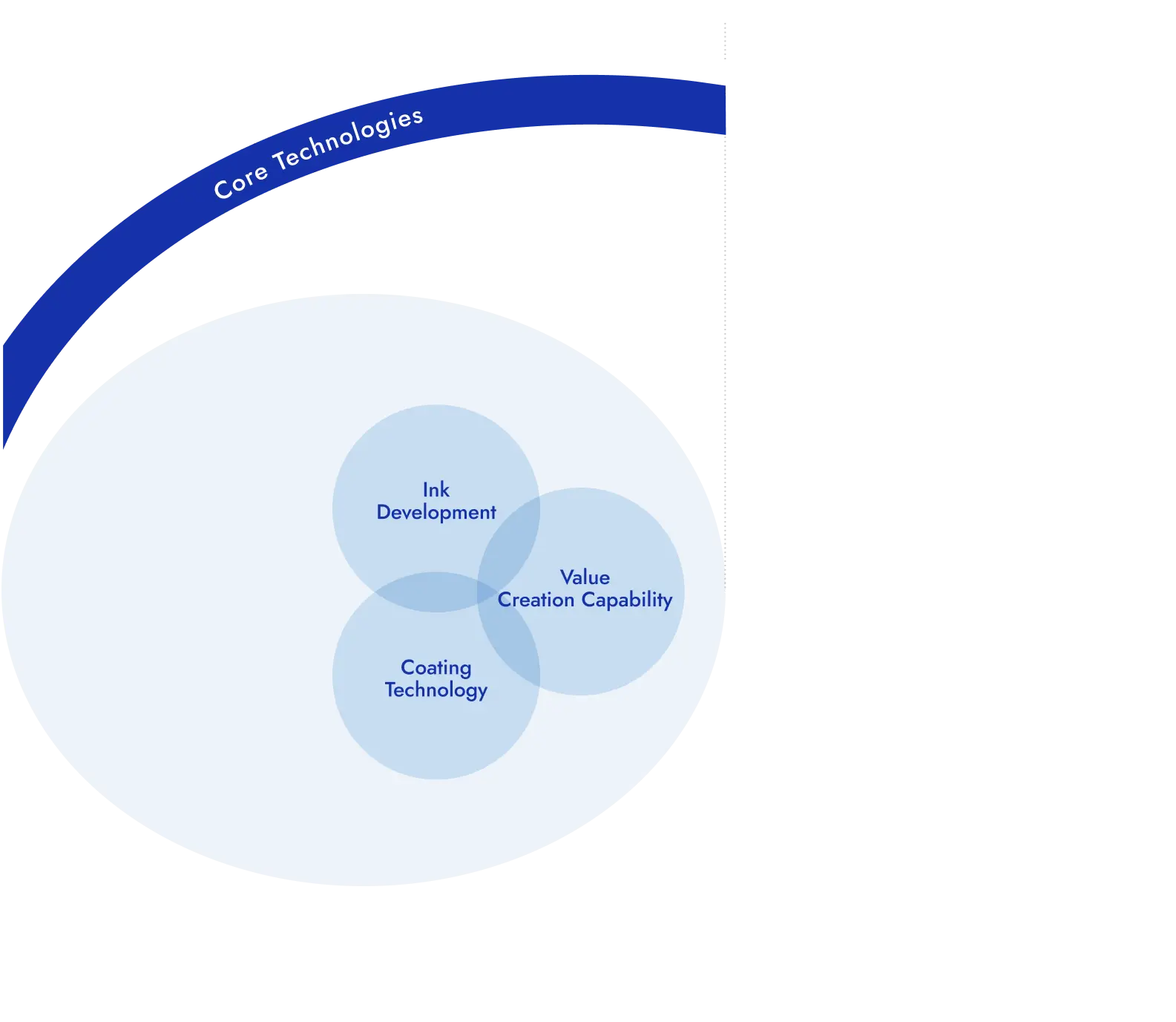

Our core technologies in ink and coating are widely utilized in various fields, from everyday applications such as the food and medical industries to business sectors like manufacturing and logistics. Explore our diverse business domains and case studies.

View Business Overview

MANUFACTURING & TECHNOLOGY

MANUFACTURING

& TECHNOLOGY

We offer products that meet stringent quality standards both domestically and internationally, thanks to our integrated in-house manufacturing system and advanced technical expertise. Discover our process, from carefully selected raw materials and precise design to rigorous quality control, to create products that exceed customer expectations.

View Manufacturing & Technology

FACILITIES & FACTORIES

FACILITIES

& FACTORIES

Our facilities are equipped with multi-functional systems, including clean rooms and high-temperature heating devices, enabling the coating and processing of electronic components and precision instruments. Centered around our Shiga factory, we collaborate with global locations to provide technologies that meet the needs of customers worldwide.

View Facilities & Factories

Multi-Headed Coater Multi-head Coater

A device capable of simultaneously applying multiple layers of ink, enabling efficient production. Our multi-headed coater is capable of adding heat resistance and multifunctionality while supporting mass production at a processing speed of up to 500 meters per minute.

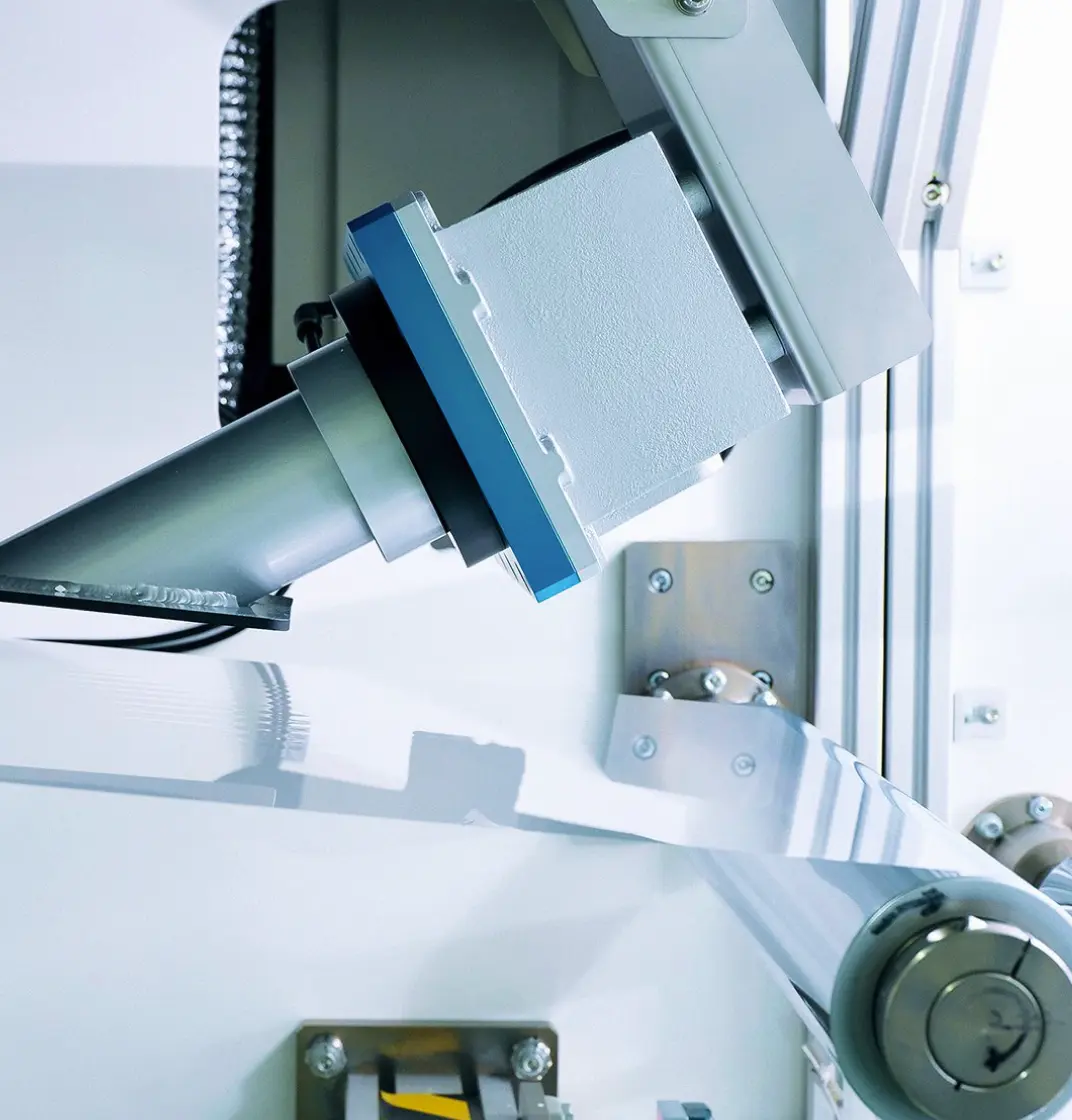

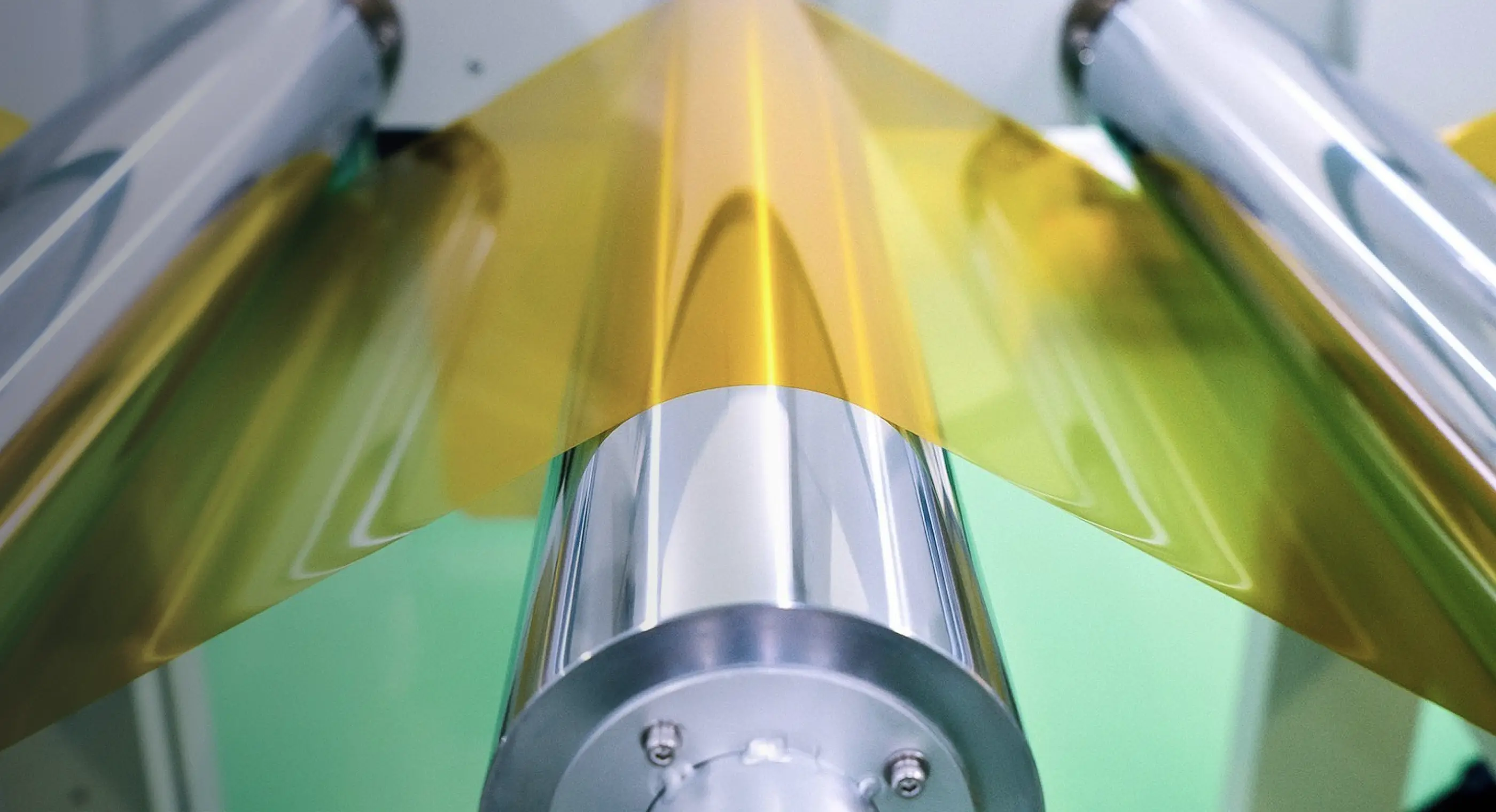

View More View MoreClean Coater Clean Coater

A coating machine equipped with a clean environment for processing precision electronic components. Our clean coater includes rollers compatible with metal foils and drying ovens capable of handling temperatures up to 200°C, ensuring high-quality coatings from thin to thick applications.

View More View More

Roll-to-Roll

High-Temperature

Heating Device

Roll to Roll

High Temperature Heating Device

A high-temperature processing system capable of reaching 400°C, enhancing the durability and heat resistance of electronic components. By adjusting the nitrogen atmosphere and conveying methods, it accommodates various coated products and substrates.

View More View MoreSlitter Slitter

A system capable of slitting thermal transfer ribbons down to a minimum width of 6mm. Equipped with high-precision cameras to detect and remove defects, ensuring high-quality product supply.

View More View More

PRODUCTS

PRODUCTS

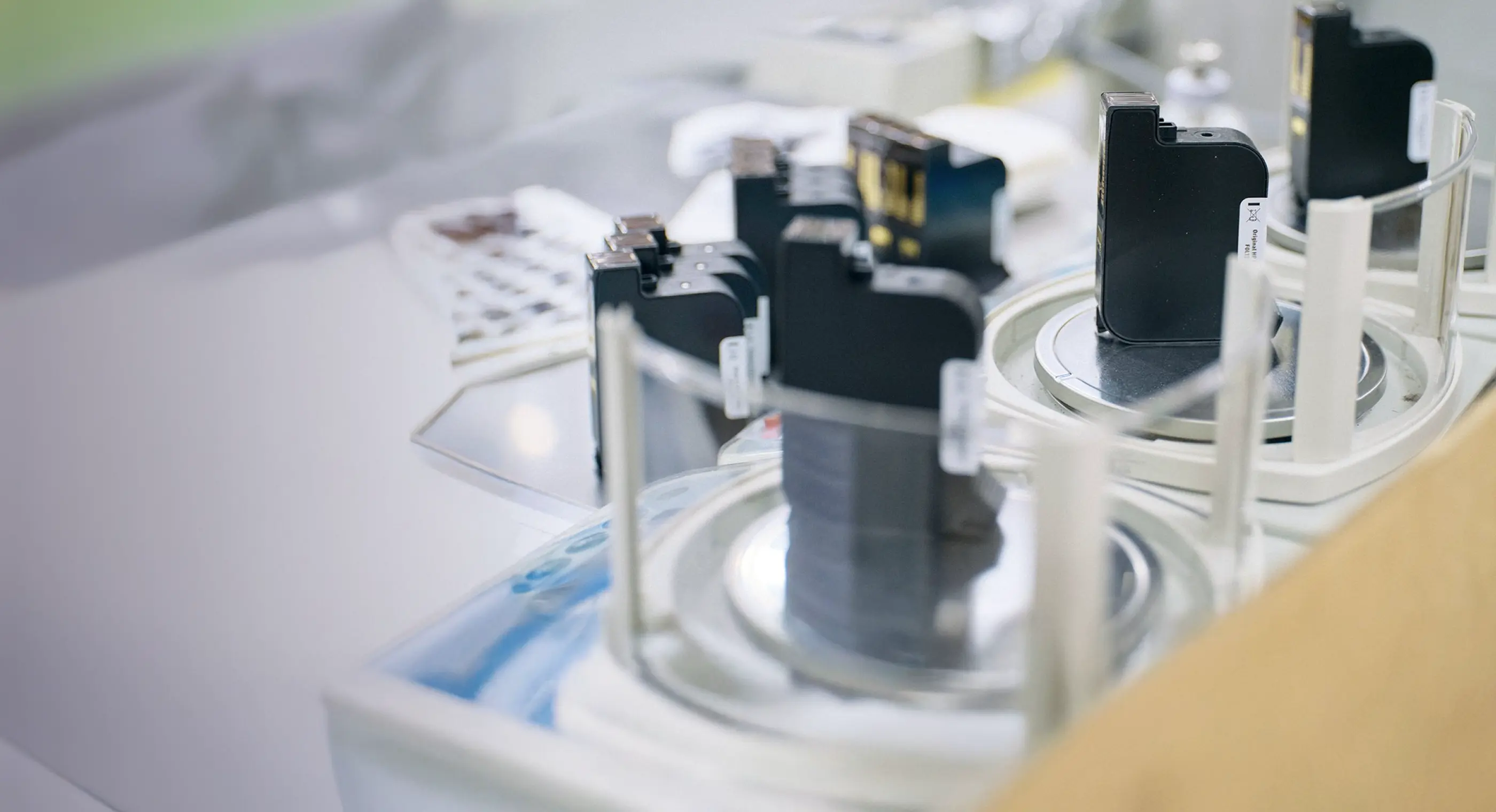

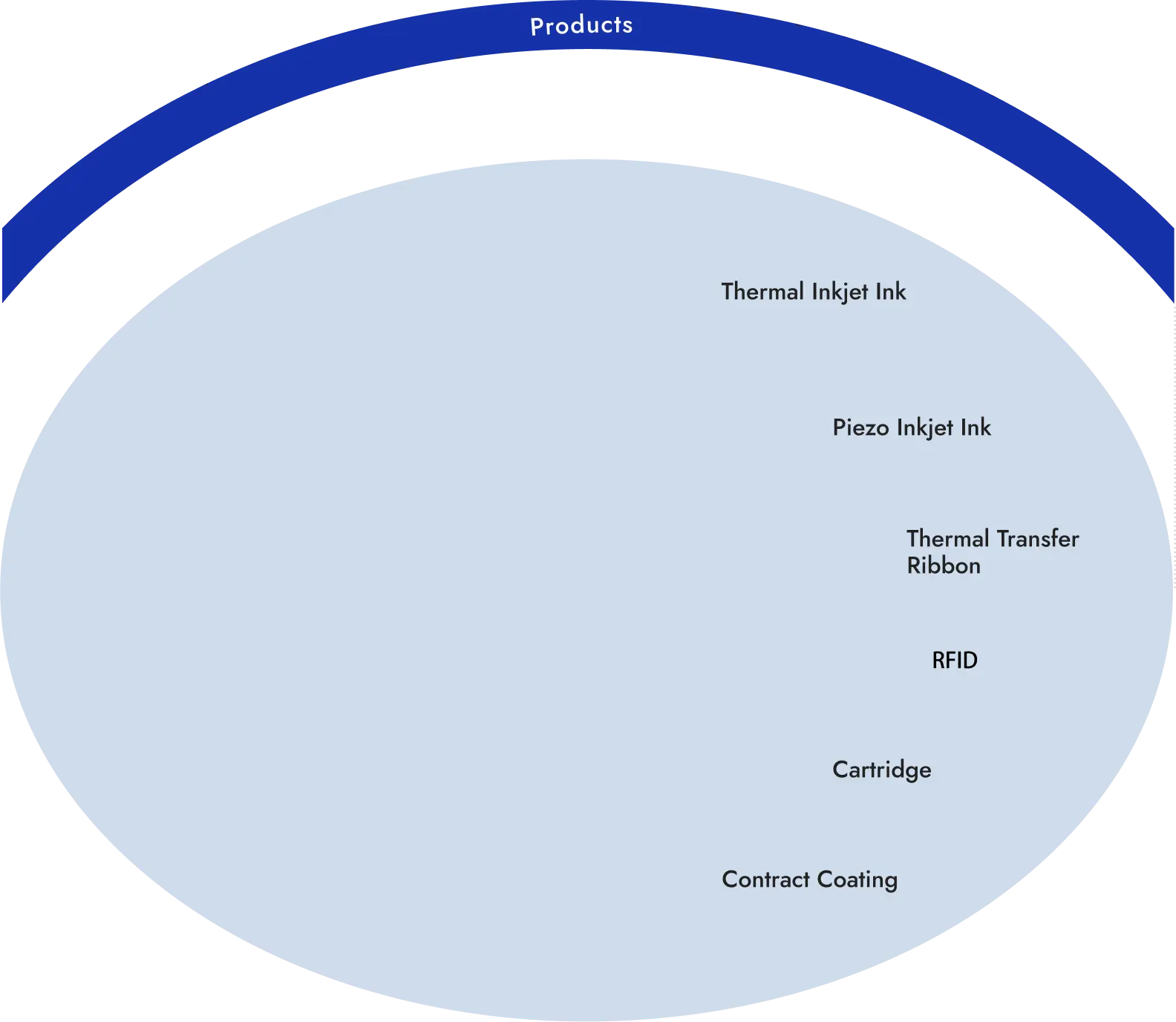

We offer a wide range of products that support daily life, including thermal transfer ribbons and inkjet inks suitable for marking and coding variable information in the manufacturing process, as well as RF tags for production management. From food and pharmaceuticals to logistics and automotive industries, our products cater to various customer needs.

View Products

DISCOVER GENERAL

DISCOVER

GENERAL

Uncover the journey of General,

a company with over 100 years of history—exploring

the challenges we've taken on and the transformations

we've undergone through milestones and key numbers.

HISTORY OF TRANSFORMATION

HISTORY OF

TRANSFORMATION

Born in the Taisho era, we have continuously pursued advancements in ink development and coating technology while evolving with the times beyond these fields. Through business expansion both domestically and internationally and the adoption of cutting-edge equipment, we lead the industry. Explore our history of challenges and transformation.

View History of Transformation

NUMBER

GENERAL IN

NUMBERS

NUMBERS

What kind of company is GENERAL?

Find the answers through key numbers.

NEWS

NEWS

[Shiga Lakes] Announcement of Sponsorship Agreement

Exhibition Announcement :Sino-Pack 2026

Investigation Regarding Potential Information Leakage (Final Report)

Contact

CONTACT

For inquiries regarding contract manufacturing or products,

please feel free to contact us here.