CSR

CSR

- Top

- CSR

Environmental Contribution Company – GENERAL

To realize a sustainable future, we have promoted environmentally conscious initiatives from an early stage. Aiming for carbon neutrality, we focus on utilizing renewable energy and implementing harmless measures in our factories. We are also committed to contributing to the local community and the environment in Shiga Prefecture. Here, we introduce specific CSR activities and environmental initiatives we are pursuing.

01 Introduction of Solar Power Generation System

Generating 310,000 kWh of electricity annually with solar power.

Contributing to environmental protection.

At our distribution center and plant located in Koka City, Shiga Prefecture, we installed a solar power generation system to reduce our environmental impact. Installed about 20 years ago, the system consists of 1,536 panels (total generation capacity of 353kW) and generates approximately 310,000 kWh of electricity annually, covering about one-third of the facility's total annual electricity consumption. This amount is equivalent to the energy usage of about 120 average households. It helps reduce our CO2 emissions and supports local environmental improvement activities.

Facility Overview

Installation Location: Satsukigaoka 5-banchi, Minakuchi-cho, Koka City, Shiga Prefecture

Solar Power Installation Area: 2,535㎡ 1.65㎡ per panel, (generating capacity of 230W per panel) × 1,536 panels

Expected Annual Solar Power Generation: About 310,000 kWh (1/3 of facility electricity usage)

02 Production Plants Not Generating a Negative Impact

Proper disposal of waste such as exhaust gases and solvents.

Building a sustainable manufacturing system.

We have been committed to realizing plants that do not generate a negative impact for many years. By introducing equipment for the proper treatment of exhaust gases and solvents at an early stage, we have established a sustainable manufacturing system.

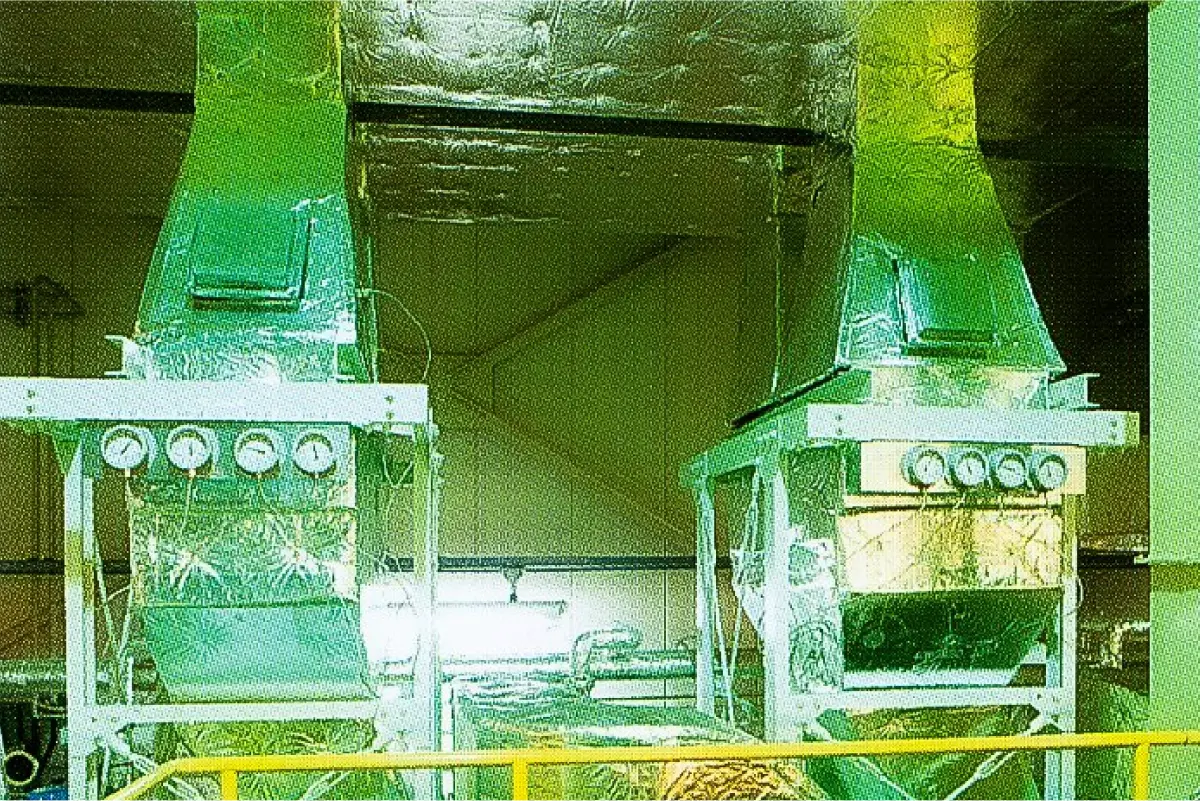

Exhaust Gas Combustion Device

Exhaust gases containing organic solvents generated in the coating process are burned at temperatures above 800°C to eliminate harmful substances. Some of the heat energy generated in this process is reused within the plants, contributing to improved energy efficiency.

Solvent Recovery System

This system is used to distill and reuse organic solvents emitted during the ink manufacturing process. It efficiently recovers reusable solvents, mainly toluene and methyl ethyl ketone (MEK), reducing the environmental impact.

Dust Collectors

Dust generated during the ink formulation process is collected, preventing it from being released into the atmosphere. This is effective in improving the working environment and preventing air pollution, contributing to the overall cleaning of the manufacturing process.

Waste Heat Recovery Device

The heat energy from high-temperature exhaust gases generated in the production process is recovered and reused in the drying process. This process reduces energy consumption and achieves efficient energy utilization.

ISO9001 and ISO14001 Certifications

Solid Commitment to Environmental Conservation.

With our basic policy of ensuring quality and harmony with the environment, we have acquired ISO9001 and ISO14001 certifications, taking environmental protection as a key social responsibility. We also adhere to Shiga Prefecture's strict water quality management standards and are actively engaged in protecting the water environment around Lake Biwa.

Contact

CONTACT

For inquiries regarding contract manufacturing or products,

please feel free to contact us here.