Radio Frequency Identification

RFID

Full Support for RFID Introduction – Driving DX in Manufacturing and Other Industries

From system design to on-site implementation and RF tag configuration tailored to your operations, we provide solutions that address your specific challenges—contributing to greater efficiency and improved accuracy in inventory and asset management.

- What is RFID?

- RFID (Radio Frequency Identification) is an automatic recognition technology that communicates with recording media such as RF tags using radio waves or magnetic fields to read or overwrite information.

As a member of the Japan Automatic Identification Systems Association (JAISA), we promote the efficiency and advancement of systems in manufacturing, logistics, and distribution through the use of RFID technology.

Product Features POINT

Primarily serving the manufacturing industry facing challenges in digital transformation (DX), we provide comprehensive support from RFID adoption planning and system design to tag selection and on-site implementation.

Point.01 Selecting and Developing Optimal Tags

We propose optimal, high-quality RF tags tailored to your specific on-site environment. Even for needs that are difficult to meet with existing product lineups, we respond with customized solutions and externally sourced items through our unique supply channels.

Point.02 Flexible System Design

In addition to the RF tags designed by General, we collaborate with system developers and reader equipment manufacturers to provide flexible system designs tailored to each customer's needs. By proposing optimal solutions, we help achieve seamless operations suited to each business environment.

Point.03 Total Support from Planning to Field Operations

We provide on-site support to help establish the necessary environment for operating RFID systems. Through tailored consulting based on your specific conditions, we propose the optimal setup that enables smooth reading and accurate data management.

Various RFID Tags LINEUP

We offer a diverse lineup of products designed to meet a wide range of usage environments. Here are some examples of items specifically developed for use in specialized conditions and applications.

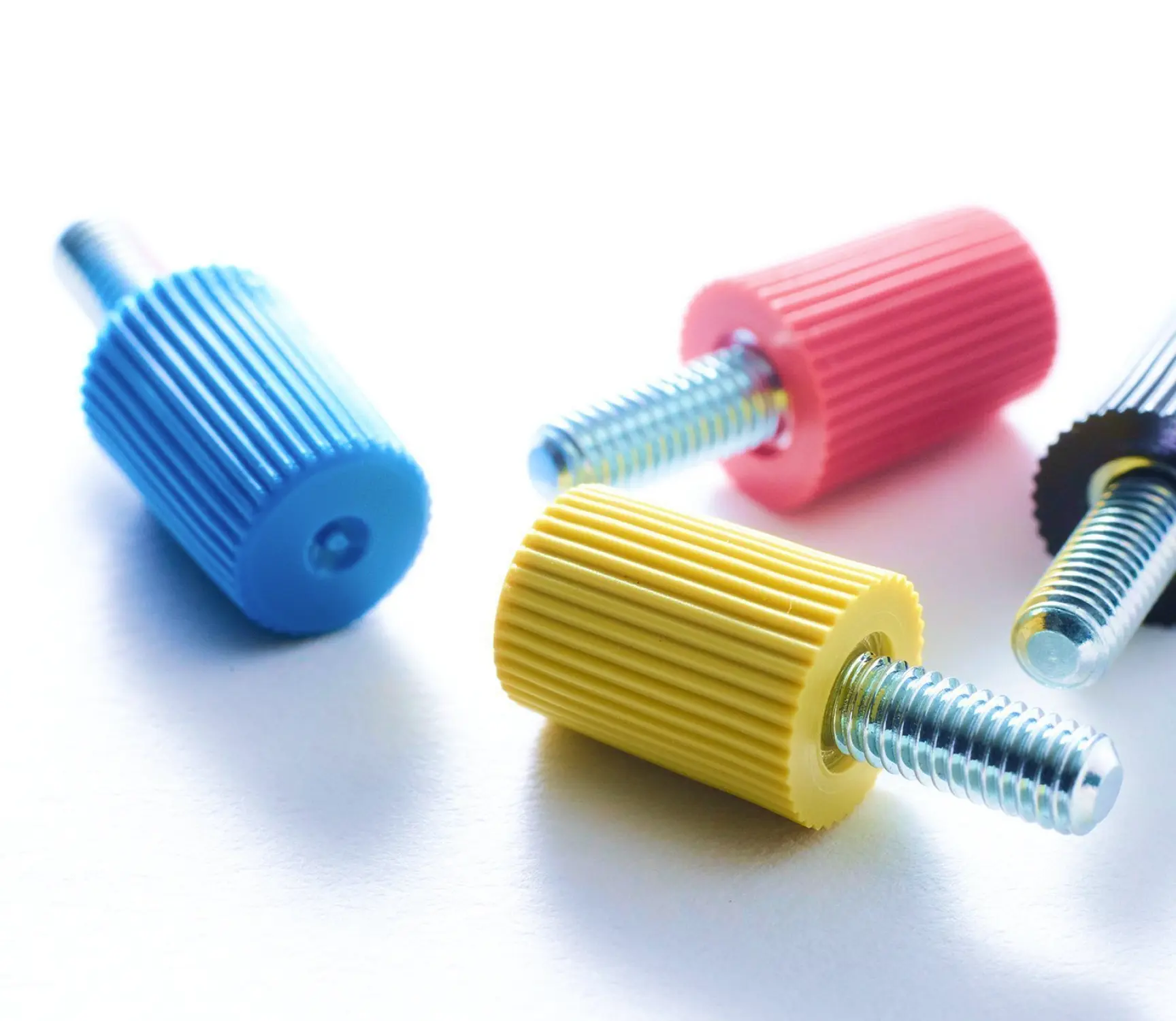

Type.01Screw-Type RF Tag

This metal-compatible tag attaches a plastic molded IC tag to the head of a screw and is resistant to moisture and shock. It’s durable and easy to install, making it ideal for outdoor and harsh environments. Despite its compact size, it has high sensitivity.

Type.02Helical-Type RF Tag

This tag is capable of maintaining stable communication even when installed directly on metal surfaces. Its ability to operate reliably in metal-rich environments makes it suitable for use in manufacturing processes and asset management. To ensure durability, it is commonly enclosed in a protective tube and used in a strap-like form.

Type.03Washer-Type RF Tag

This tag is primarily used in place of washers for mechanical parts. It can be securely fixed to parts using screws, making installation easy and durable.

USE CASES USE CASES

Here are some examples of implementation cases that utilize our diverse product lineup.

Use Case.01 Manufacturing Process Management

By utilizing RFID, you can manage each stage of the manufacturing process in real time. Tracking the progress of manufacturing and the location of each component enables traceability and tracking of production history, which is essential for quality control.

Use Case.02 Maintenance Inspections and Asset Management

RFID is effective for managing expensive equipment and tools requiring regular maintenance. By tracking the usage and storage locations of tools and machines in real time, the risks of unused items, loss, or expired calibrations can be reduced, improving the accuracy of asset management. This improvement in accuracy leads to reduced maintenance costs and improved operational efficiency.

Use Case.03 Product and Inventory Management

In logistics and warehouse management, RFID readers scan tags attached to individual items, enabling real-time tracking of inventory and shipment status. This eliminates the need for manual data entry and enhances operational accuracy.

Product Introduction Video VIDEO

(Co-produced with our group company)

PRODUCTS PRODUCTS

Contact

CONTACT

For inquiries regarding contract manufacturing or products,

please feel free to contact us here.