Manufacturing & Technology

MANUFACTURING

& TECHNOLOGY

MANU-

FACTURING &

TECHNOLOGY

- Top

- Manufacturing & Technology

A One-Stop Manufacturing System and

Unique Technological Capabilities

to Meet Any Need

We have a fully integrated in-house manufacturing system that covers all production processes, along with highly specialized expertise in various fields. From sourcing carefully selected raw materials to precise manufacturing processes and rigorous quality control, we meet high domestic and international quality standards. Here, we introduce our unique manufacturing and technological capabilities tailored to our customers’ needs.

FLOW

FLOW

- 01Raw Material Selection

- 02Ink Design & Formulation

- 03Coating Technology

- 04Slitting Technology

- 05Filling, Assembly & Packaging

- 06Inspection & Analysis

- 07Shipment

Carefully Selected Raw Materials that Meet Safety Standards

We carefully select raw materials that meet safety and regulatory standards. By conducting thorough quality inspections from the procurement stage, we ensure manufacturing process stability, contributing to enhanced quality and a stable supply of products. To meet diverse domestic and global demands, we also select materials that comply with international standards.

- Technology TECHNOLOGY

-

- 01Compliance with stringent regulations and standards

- 02Selection of materials suitable for global use

Optimizing Ink Performance and Physical Properties to Meet Customer Needs

We formulate inks with a range of physical properties—such as viscosity, particle size, and solid content—tailored to meet specific performance requirements and applications. By utilizing mixing equipment of various sizes with temperature control ranging from 10°C to 150°C, we ensure stable ink quality that is unaffected by seasonal or environmental changes.

- Technology TECHNOLOGY

-

- 01Production and sale of high-value-added inks using various equipment

- 02Manufacturing environment optimized with precise temperature control

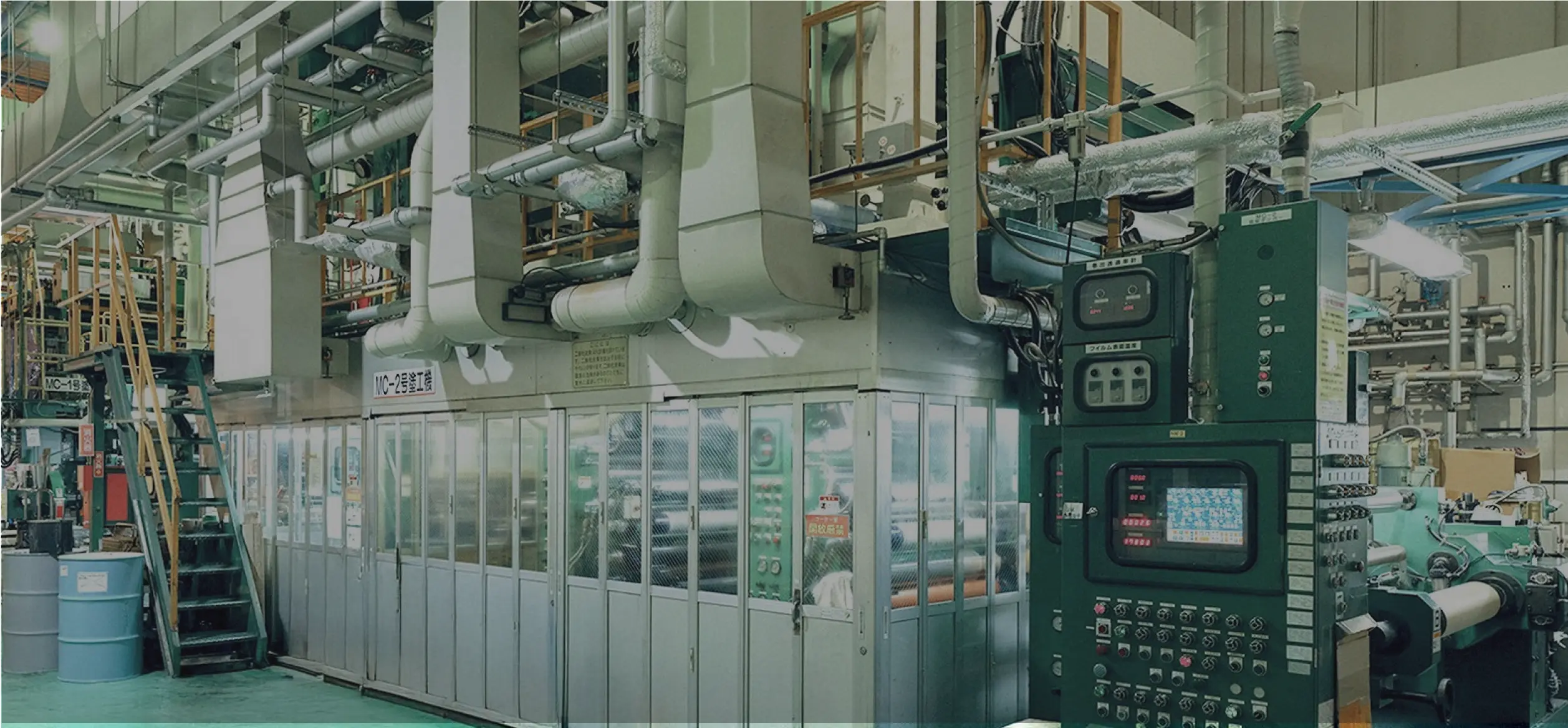

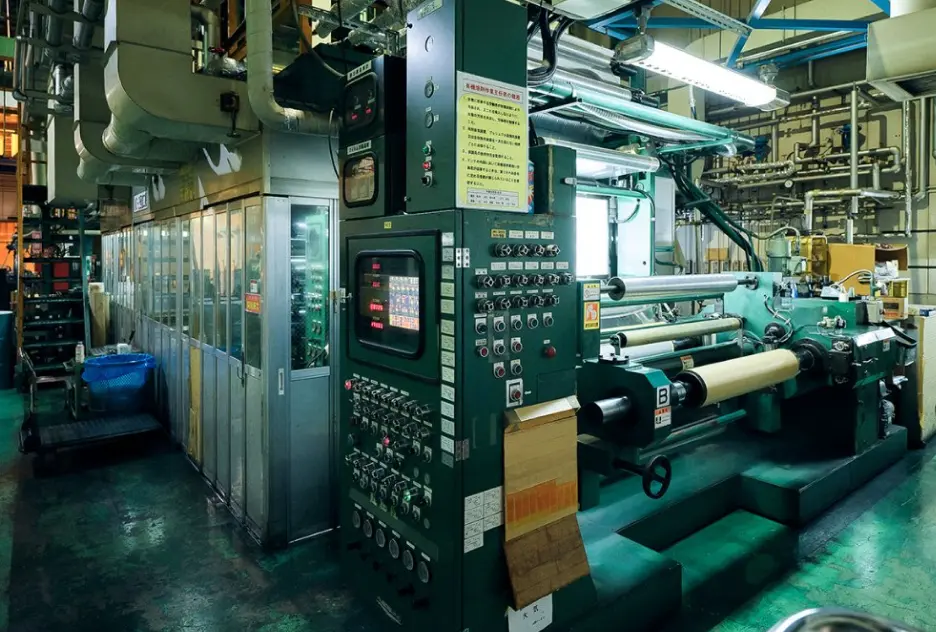

Specialized Equipment for Efficiently Enhancing Functionality and Durability

We have introduced a high-precision multi-headed coater capable of applying multiple layers simultaneously and uniformly. Equipped with an abnormality detection system, this system instantly identifies and corrects even the slightest irregularities or defects. Through meticulous control and advanced coating technology, we maintain product reliability and consistently deliver high-quality products.

Multi-Headed Coater

A multi-headed coater capable of high-speed and various types of multi-layer coatings. This technology enables the simultaneous application of different ink types, enabling the provision of different properties such as durability and abrasion resistance in a single process. Consequently, high-quality and cost-effective products can be provided.

View More View More

Detection System

Using a CCD camera-based abnormality detection system, we promptly identify surface irregularities, ensuring swift corrective action and maintaining consistent coating quality. This system enables a quick response when problems occur and ensures the uniformity of coating surfaces.

- Technology TECHNOLOGY

-

- 01Products with multiple functionalities with multi-headed coaters

- 02Diverse coating processes, including adhesion and release treatments

Precision Processing of Films, Adhesive Materials, and Aluminum Foils No Problems with Processing Other Materials Besides Film as well

Our slitting technology allows precise processing of various materials, including films, paper, and aluminum foil. We can slit raw materials up to 1000mm wide into ultra-fine widths as small as 6mm, providing flexible solutions tailored to customer needs.

View More View More- Technology TECHNOLOGY

-

- 01Slitting expertise based on a wide range of achievements

- 02CCD camera-based ribbon defect detection system for quality assurance

Automated Processes from Filling to Packaging Aligned with Product Specifications

The filling and packaging processes are handled by state-of-the-art automated lines. For inkjet ink cartridge filling, labeling and vacuum packaging are automatically conducted after filling, and product inspections ensure high-quality final products. Our thermal transfer ribbon products are assembled into cartridges to meet assembly and packaging specifications. We pay a great deal of attention to maintaining quality by using manual inspection at the final stage as well.

- Technology TECHNOLOGY

-

- 01Promoting automation in every stage of the manufacturing process

- 02A robust production system capable of mass production

Multifaceted Testing and Environmental Assessments for Quality Assurance

We conduct rigorous quality inspections and analyses, including ink viscosity, particle size distribution, and coating surface properties. Utilizing fluorescence X-ray analysis and surface composition analysis, we quantify the product quality of each product for accurate management. Environmental durability tests, such as weather resistance and abrasion resistance, ensure our products can withstand extended use under external environments.

- Technology TECHNOLOGY

-

- 01Quality inspection from every angle

- 02Environmental testing to simulate real-world usage conditions

Efficient Shipping with the Latest Picking System

To increase shipping speed and packaging accuracy, we introduced an advanced picking system. Optimizing product location and picking order minimizes warehouse movement, allowing for efficient retrieval. This system enables immediate picking regardless of product packaged appearance, significantly accelerating the speed of shipping operations.

- Technology TECHNOLOGY

-

- 01Efficient warehouse flow to reduce unnecessary movement

- 02Picking processes adapted to product shape and packaging conditions

A Comprehensive Production

Management System and

World-Class Equipment &

Technology to Meet All Needs

Contact

CONTACT

For inquiries regarding contract manufacturing or products,

please feel free to contact us here.