Facilities & Factories

FACILITIES &

FACTORIES

- Top

- Facilities & Factories

Advanced Equipment and

Manufacturing System to Meet

Global Needs

We have multifunctional manufacturing equipment that supports precision processing, enabling us to handle a wide range of coatings and processing for various electronic components and precision instruments. The equipment is capable of meeting the requirements for clean environments, high-temperature processing, multi-layer structures, and high heat resistance. By enhancing both productivity and quality, we cater to diverse domestic and international needs. Additionally, we are committed to building sustainable production practices by introducing environmentally friendly equipment.

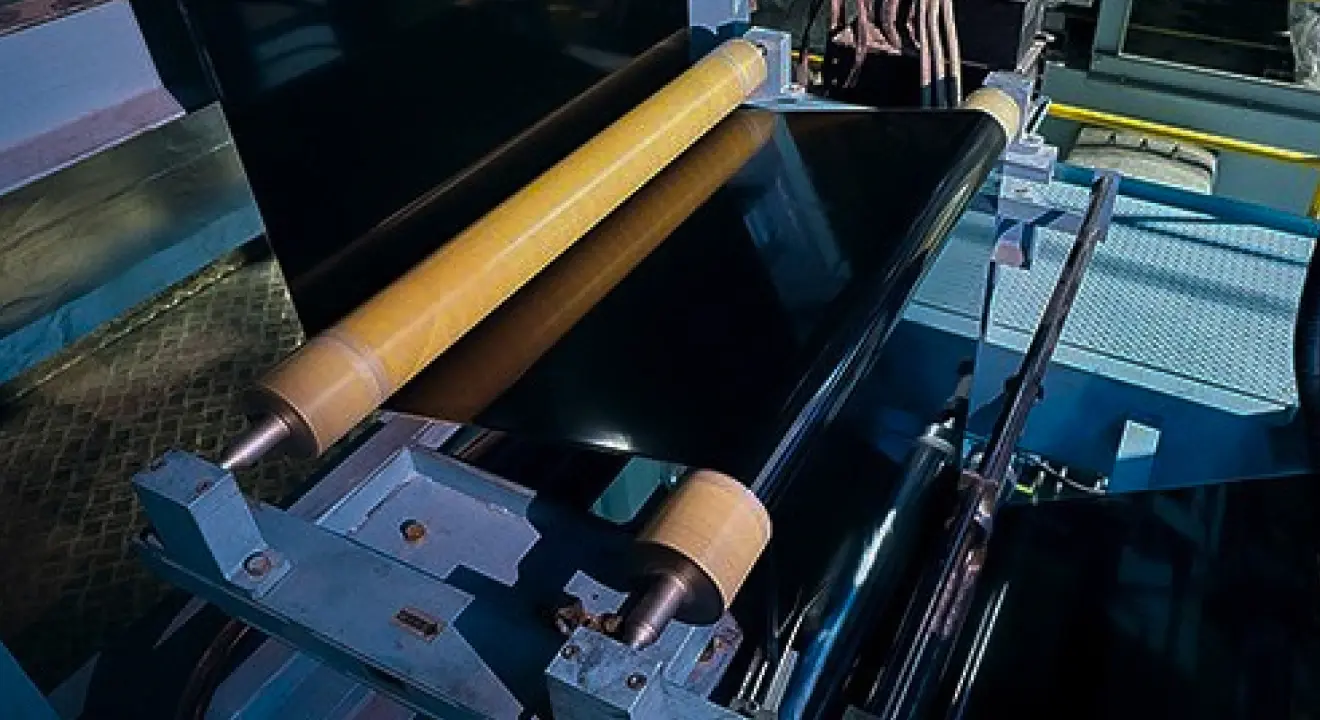

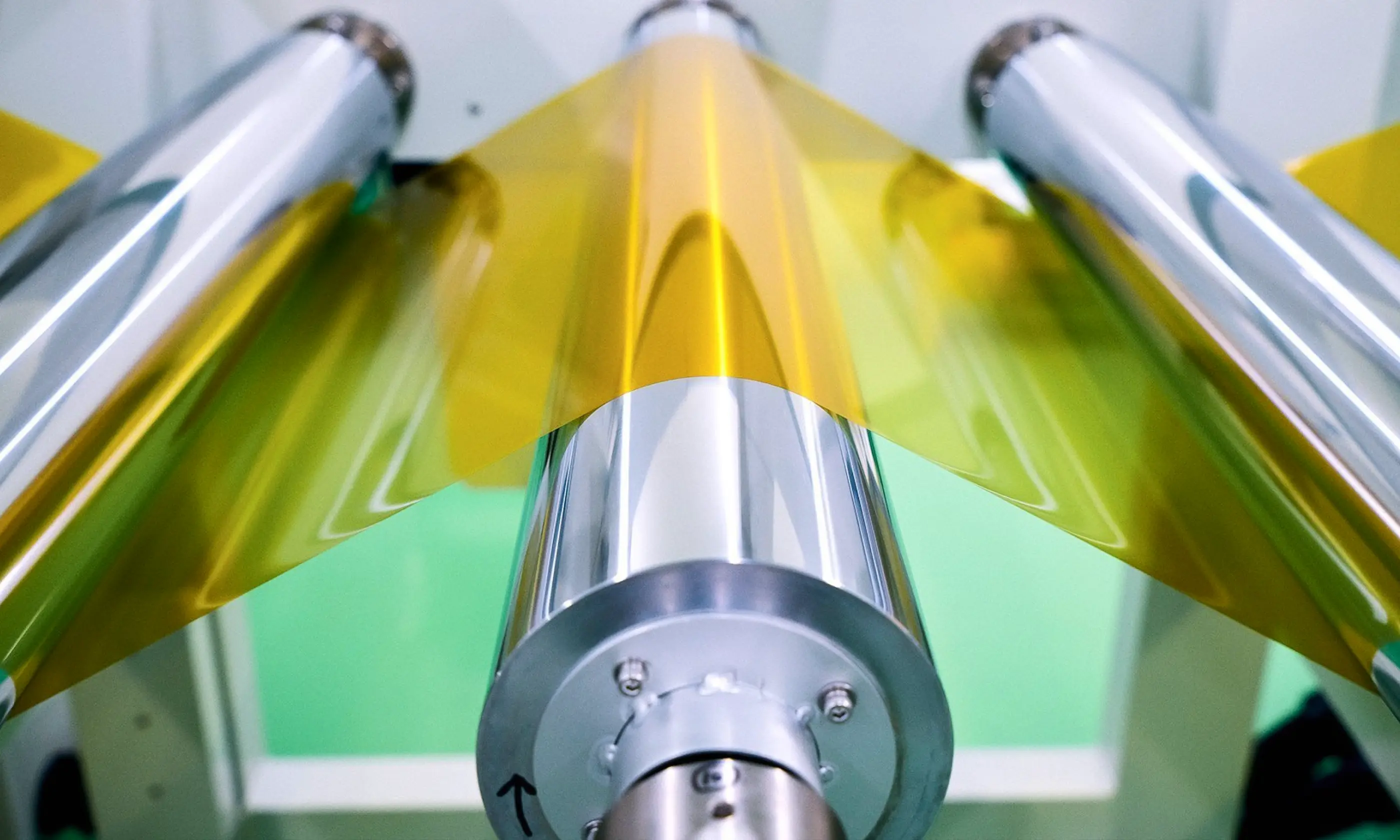

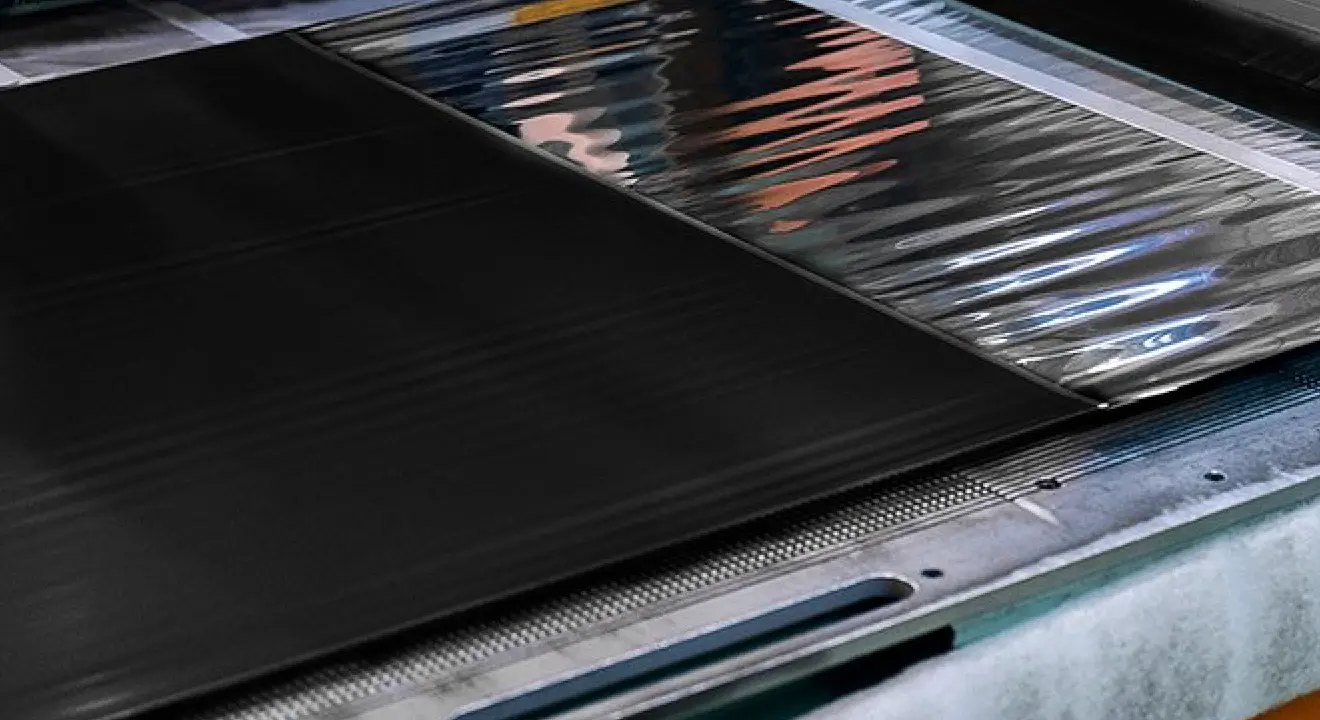

Multi-headed coater Multi-headed coater

A high-performance device capable of applying multiple layers of ink simultaneously, which is essential for manufacturing thermal transfer ribbons. With a maximum of five layers of coating, this machine enables a more efficient and faster production compared to traditional methods. It can process films at a speed of up to 500 meters per minute, preventing production stagnation. By combining wax-based and resin-based ink layers, the machine is also able to realize products with multiple functions and high durability.

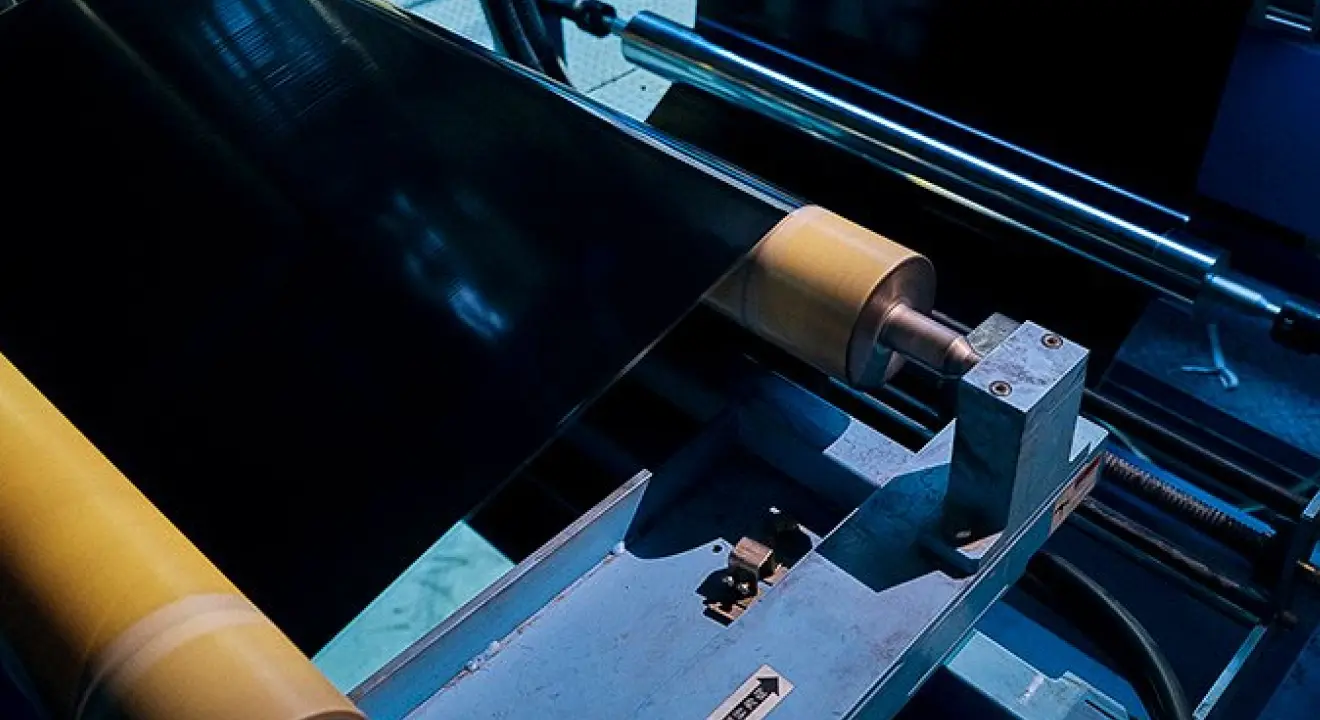

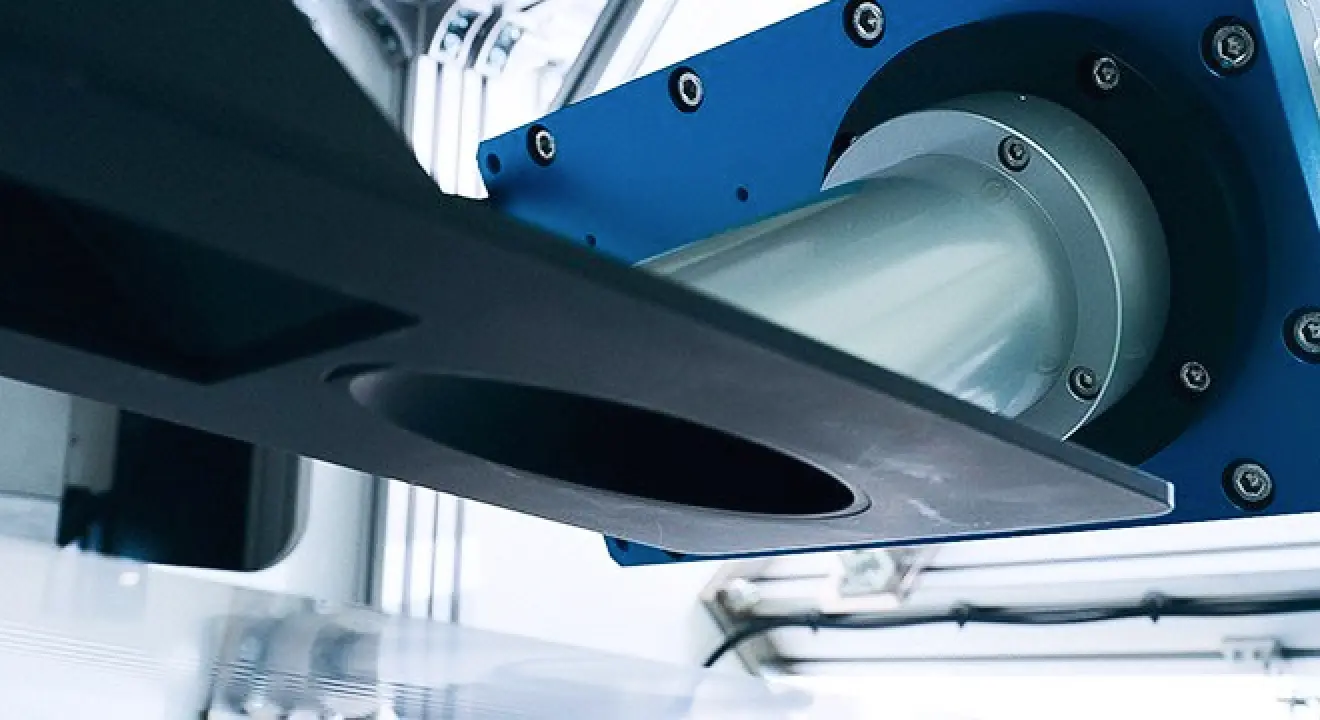

Clean Coater Clean Coater

This equipment is adapted even for precision electronic component coatings and operates in a cleanroom environment free from dust and contaminants. It is especially suitable for handling delicate materials such as metal foils. Equipped with a drying oven that can handle temperatures up to 200°C, it is also ideal for components requiring heat resistance. Two coating methods, small-diameter gravure and knife coating, enable flexible application from thin to thick coatings, ensuring high-quality, diverse product processing.

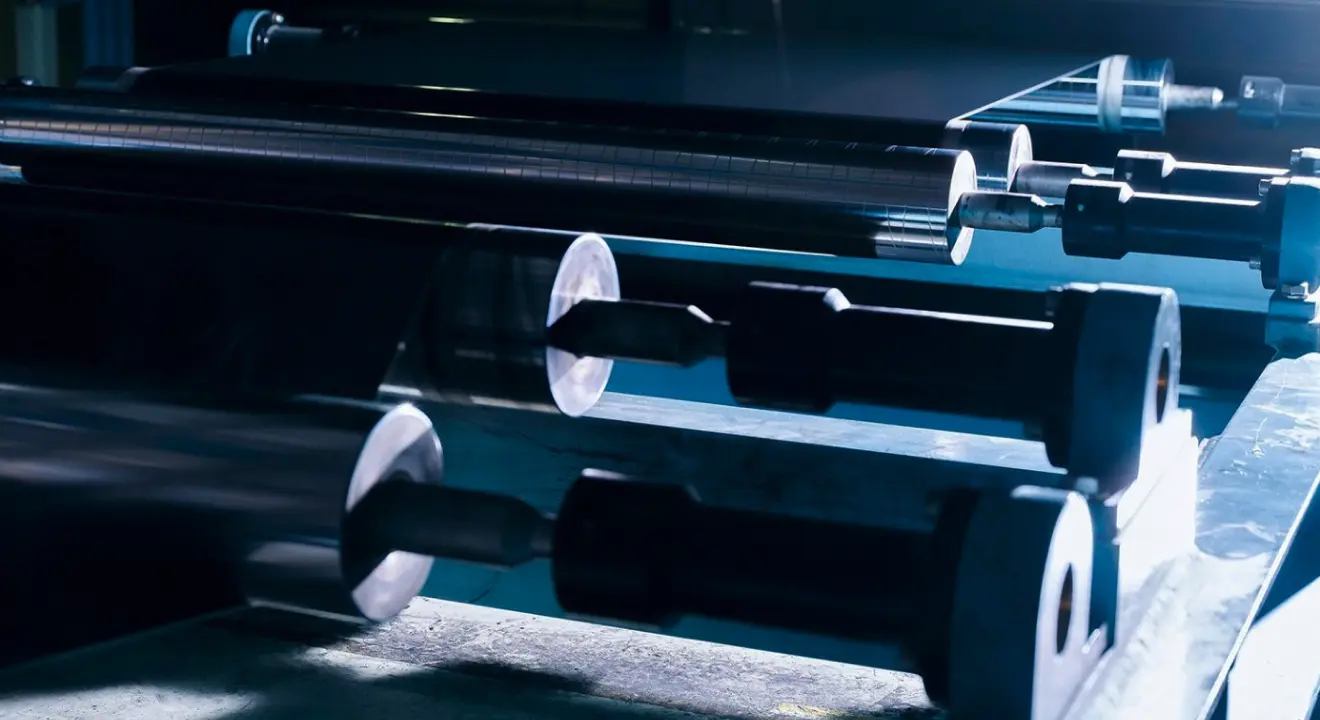

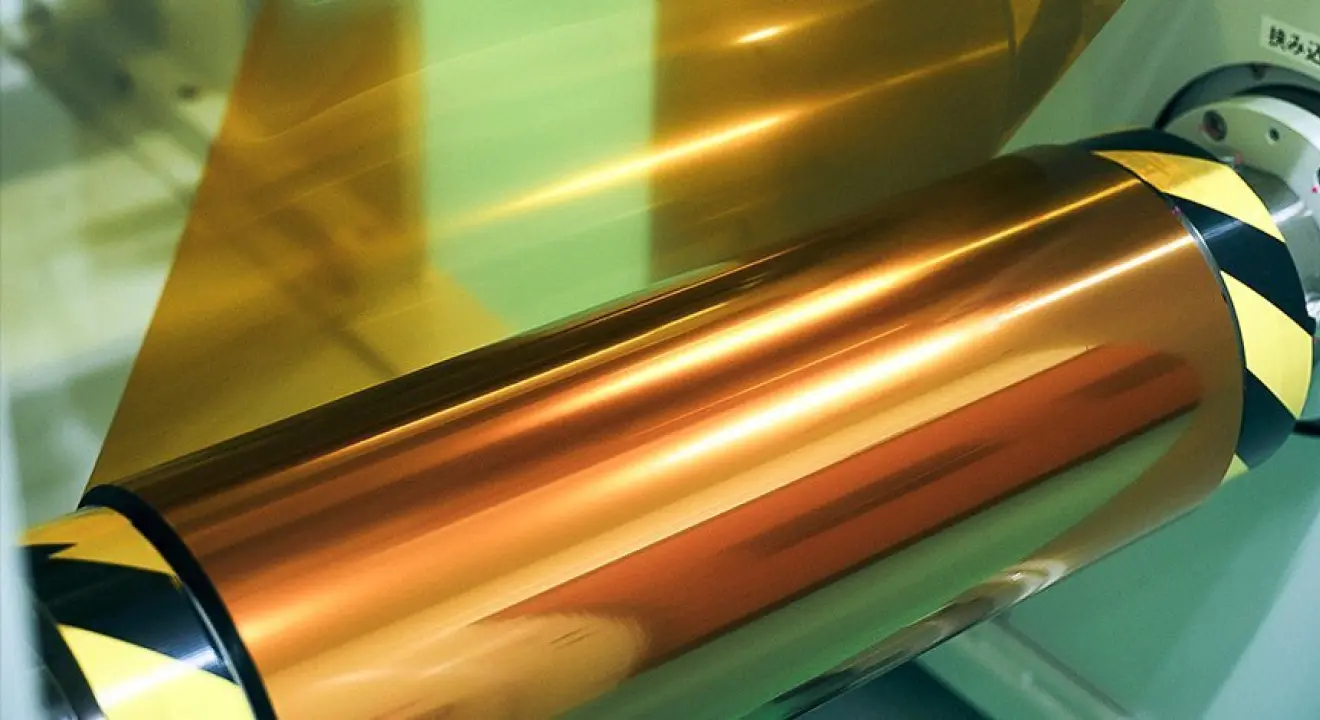

Roll-to-Roll

High Temperature Heating Device

Roll-to-Roll

High Temperature Heating Device

This device enhances the durability and heat resistance of coated films including resin and metal foils, which are components of the products that need to be heat resistant, by baking. Processing can be performed in a nitrogen atmosphere, preventing oxidation during baking. It can also handle double-sided coatings by adjusting the transport method, ensuring uniform treatment without contact with guide rolls. Like the Clean Coater, it operates in a cleanroom environment, making it ideal for electronic materials.

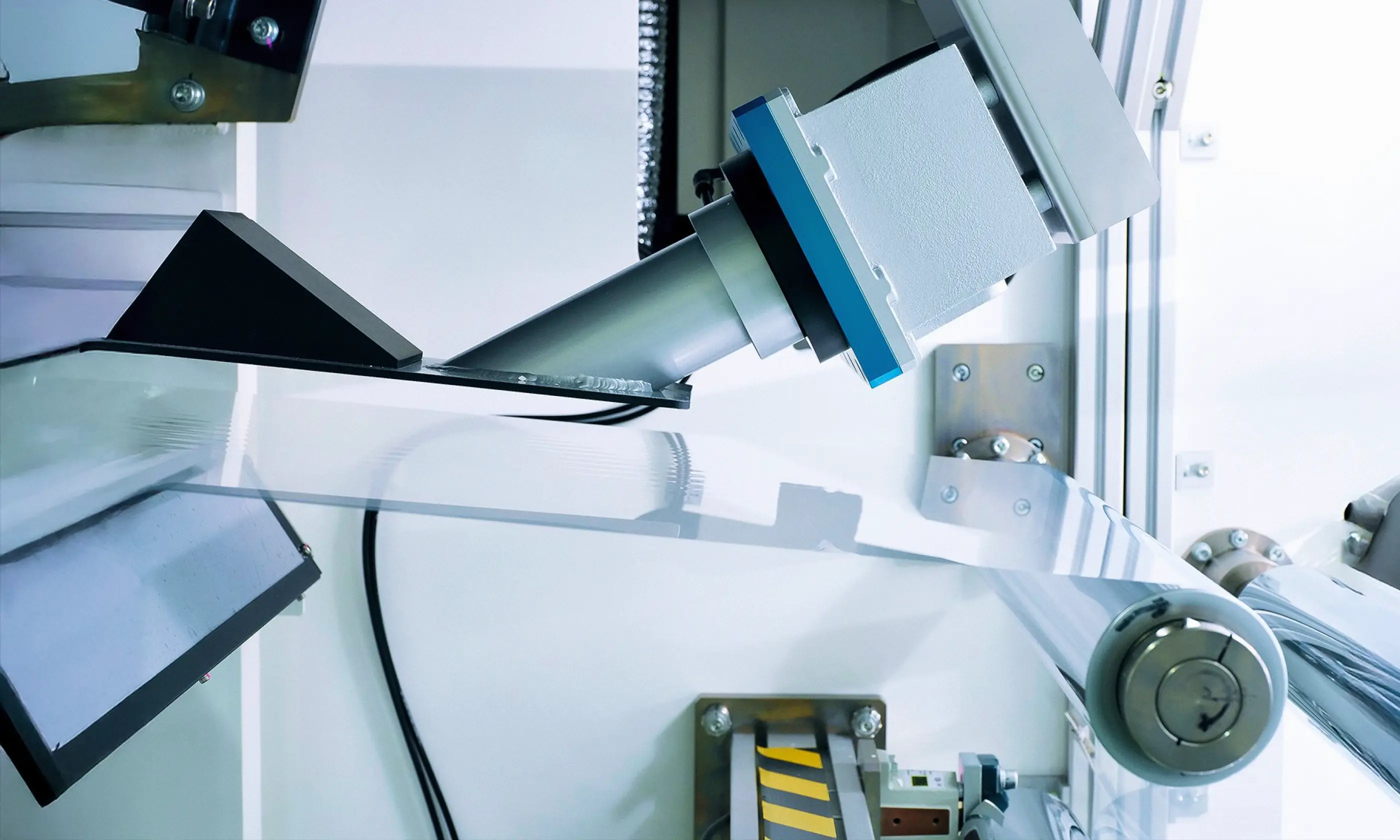

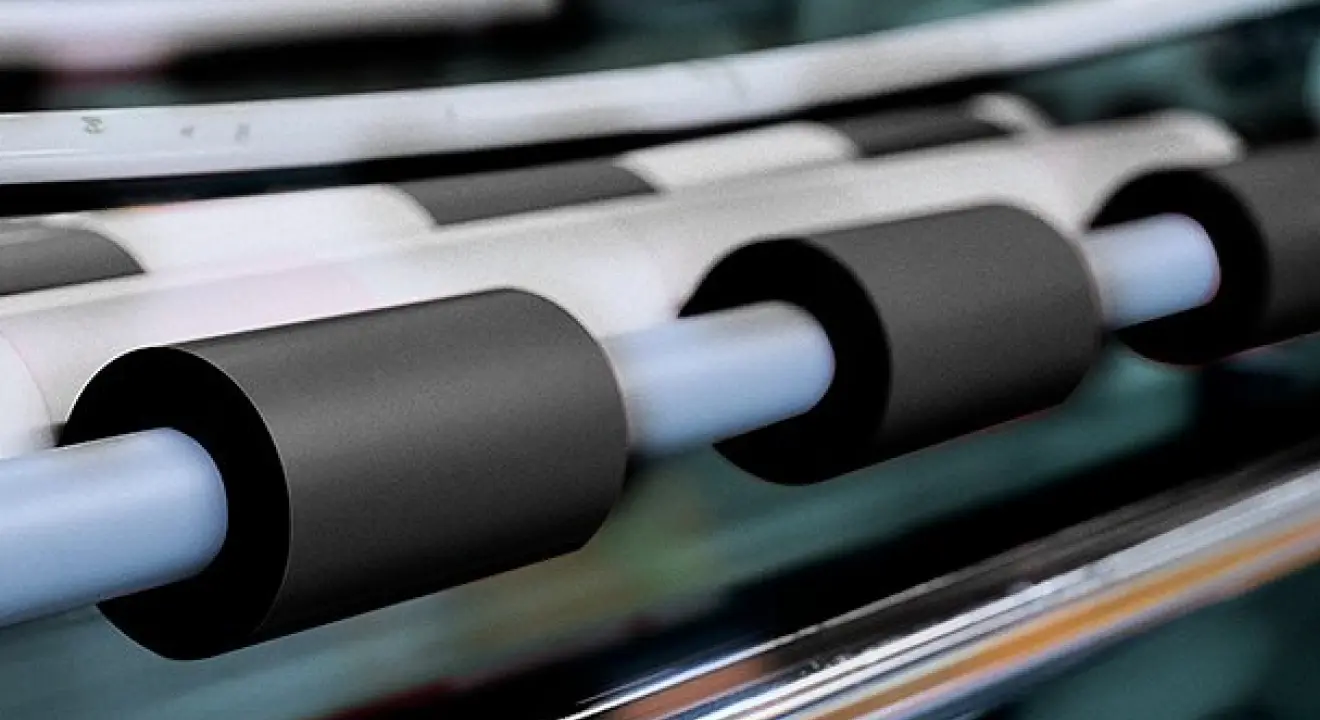

Slitter Slitter

This equipment slits thermal transfer ribbons and other materials to customer-specified widths, with a minimum width of 6mm. It provides ribbon widths suitable for various printers, enabling customized products to meet client needs. Additionally, a high-precision camera detection system mounted in the slitting process automatically identifies and removes coating defects, ensuring high-quality product supply and precise slitting.

A Global Production System for

High-Quality Product Supply

Our main production facilities are located in Japan, Malaysia, and China, ensuring a globally connected supply chain. With the Shiga Factory as our mother plant, our Malaysia and China factories maintain Japanese quality standards in their manufacturing processes. We are also committed to environmental sustainability by implementing solvent recycling systems and building sustainable production practices.

ISO 9001 and ISO 14001 Certified

We are dedicated to environmentally conscious manufacturing.

We make products that can be used without worry based on a fundamental policy of "Reliable Quality" and "Harmony with the Environment." We believe environmental conservation is a key social responsibility, and we prioritize the increasing of safety and reliability across both domestic and international production sites.

Shiga Plant

Our mother plant serves as the central hub for production management and product development across all locations. Every product is meticulously controlled under Japan's strict quality standards, ensuring stable and high-quality manufacturing. To minimize VOC emissions from the plant, we have introduced combustion treatment equipment and solvent recovery and refining systems, actively engaging in environmental protection. These environmentally conscious additions enhance the overall sustainability of our production processes and function as a part of the foundation of manufacturing for the future.

Manufacturing Equipment

- Solvent-based, hot-melt, and composite coaters

- Dry lamination coater

- Clean coater

- Roll-to-Roll high-temperature heating device

(clean coating) - Fabric ribbon coater

- Thermal roll impregnation machine

- Ink manufacturing equipment (bead mill)

- Ink manufacturing equipment

(bead mill, media-less mill)

- Ribbon slitter

- Cutting machine

- Pillow packaging machine

- Inkjet ink manufacturing equipment

- Inkjet ink filling equipment

- Paper core cutting machine (1/2 inch, 1 inch)

- Paper core notch cutting machine

Environmental Equipment

- Solvent recovery unit

- Regenerative thermal oxidizer

- Dry-type dust collector

- Waste heat recovery system

ISO Certification Obtained

Malaysia Factory GENERAL IMAGING (M) SDN. BHD.

This facility inherits the technology and quality management standards developed at the Shiga Plant. It specializes primarily in manufacturing industrial inkjet cartridges, thermal transfer ribbons, and fax ribbons. By maintaining Japanese quality standards while adopting cost-efficient production methods tailored to local economic conditions, the Malaysia Factory delivers price competitive products. Additionally, in preparation for risk during natural disasters and other emergencies, we have established a dual-production system in Japan and Malaysia to ensure stable supply during emergencies as part of our Business Continuity Plan (BCP).

Manufacturing Equipment

- Solvent-based, hot-melt, and composite coaters

- Ink manufacturing equipment (bead mill)

- Ribbon slitter

- Pillow packaging machine

- Rewinder

- Inkjet ink filling equipment

Environmental Equipment

- Dust collector

- Solvent regeneration system

ISO Certification Obtained

China Factory QINGDAO GENERAL OA SUPPLY CO., LTD.

This factory specializes in customized production and features a flexible system capable of handling small-lot, high-variety manufacturing. It has experience producing over 300 different products. Labor-intensive production processes are supported by local workforce expertise, ensuring stable output of high-quality and competitive products that cater to regional market demands.

Manufacturing Equipment

- Ribbon slitter

- Paper slitter

- Adhesive slitter

- Satin slitter

- Cutting machine

- Pillow packaging machine

- Rewinder

- Leather marker

- Fabric ribbon coater

- Fabric ultrasonic welder

- Fabric ribbon loading machine

- Automatic fabric ribbon box packing machine

- Ultrasonic welder

- Paper core cutting machine

- Drying machine

Environmental Equipment

- Dust collector

- Activated carbon exhaust system

ISO Certification Obtained

CSR

CSR

Commitment to Eco-Friendly Manufacturing

To be in harmony with our lush natural surroundings, we implement strict waste management practices. Nearly 100% of our production waste is recycled. Waste liquids and dust are collected and incinerated to thoroughly prevent leakage into the environment.

Contact

CONTACT

For inquiries regarding contract manufacturing or products,

please feel free to contact us here.