General Shiga Plant is both the company's main production facility and the heart of our comprehensive development capabilities.

As part of our commitment to creating products that stay ahead of today's evolving needs,

we are continually working to strengthen our development and manufacturing technologies and expand our production facilities.

These efforts already have helped General earn acclaim for innovative ink manufacturing,

coating, and slitting technologies, and our facilities are considered among the most advanced in the industry.

Our strategy is to constantly strengthen our technical capabilities while continuing to form cooperative, mutually beneficial relationships with companies in Japan and overseas.

This approach is fueling General growth as a pioneer and innovator in our field.

As part of our commitment to creating products that stay ahead of today's evolving needs,

we are continually working to strengthen our development and manufacturing technologies and expand our production facilities.

These efforts already have helped General earn acclaim for innovative ink manufacturing,

coating, and slitting technologies, and our facilities are considered among the most advanced in the industry.

Our strategy is to constantly strengthen our technical capabilities while continuing to form cooperative, mutually beneficial relationships with companies in Japan and overseas.

This approach is fueling General growth as a pioneer and innovator in our field.

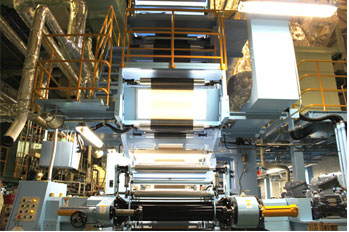

Precision, Efficiency, Innovation

Our multicolor printer features some of the industry's most advanced high-precision technologies.

Comprising 12 coating sections, the printer mainly employs a direct gravure method suitable for plane sequential coating and stripe pattern coating. The unit's outstanding drying performance helps speed up the coating process, and its one-pass multi-layer coating ability ensures high cost-performance.

With around 70 slitters, including automatic units, our Shiga Plant is fully equipped to provide a stable supply of high-quality products.

We are working to further advance our slitting technologies to meet such demands as rewinding on paper cores,

molded plastic cores and special cores.

page_br clear

FACTORY PROFILE DATA

■Shiga Plant ◎Manufacturing equipment Solvent/hot-melt/compound coater ・・・・・・・・10units Laminate coater ・・・・・・・・・・・・・・・・・・・・・・・・・3units Cleann room coater ・・・・・・・・・・・・・・・・・・・・・・1unit Roll to Roll hight heating machine(cleanroom)・1unit Fabric ribbon coaters ・・・・・・・・・・・・・・・・・・・2units Thermal sensitive roll impregnation machine・・1unit Ink manufacturing facility・・・・・・・・・・・・・・・21units Ribbon slitter ・・・・・・・・・・・・・・・・・・・・・・・・・・27units Cutter・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・1unit Form fill seal machine・・・・・・・・・・・・・・・・・・・3units RFID Inlay production machine・・・・・・・・・・・・1unit Ink Jet Ink manufacturing facility・・・・・・1unit IInk Jet Ink filling facility・・・・・・・・・・・・4units |

■Qingdao Factory Ribbon slitter・・・・・・・・・・・・・・・・・・・・・・・9units Paper slitter・・・・・・・・・・・・・・・・・・・・・・・・1unit Glue tape Slitter・・・・・・・・・・・・・・・・・・・・1unit Satin Fabric Slitter・・・・・・・・・・・・・・・・・1unit Cutter・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・1unit Form fill seal machine・・・・・・・・・・・・・・・7units Rewinder・・・・・・・・・・・・・・・・・・・・・・・・・・・・・11units Laser marker・・・・・・・・・・・・・・・・・・・・・・・・・5units Fabric coating machine・・・・・・・・・・・・・・・3units Fabric ultrasonic Welder・・・・・・・・・・・・・20units Fabric ribbon loading machine・・・・・・・・14units |

◎Environmental equipment Solvent recovery equipment Storage-type exhaust gas deodorization equipment Dry dust collectors Waste heat recovery equipment |

■GIM Factory Solvent/hot-melt/compound coater ・・3units Ink manufacturing facility・・・・・・・・・12units Ribbon slitter・・・・・・・・・・・・・・・・・・・・・10units Blanking Machine・・・・・・・・・・・・・・・・・・・1unit Form fill seal machine・・・・・・・・・・・・・3units Rewinder・・・・・・・・・・・・・・・・・・・・・・・・・・・20units Ink Jet Ink filling facility・・・・・・・5units ◎Environmental equipment Dry dust collector |

ISO 14001 and ISO 9001 Acquisition A Reflection of Our Effective Environmental Systems

| At General , protecting the environment and delivering high-quality products are two of the basic principles underlying our operations. In accordance with our belief that environmental preservation is one of our key social responsibilities, we continually strive to improve environmental performance. |

|

ISO 14001 JQA-EM1316 Shiga Plant |

|

ISO 9001 JQA-QMA11341 Shiga Plant |